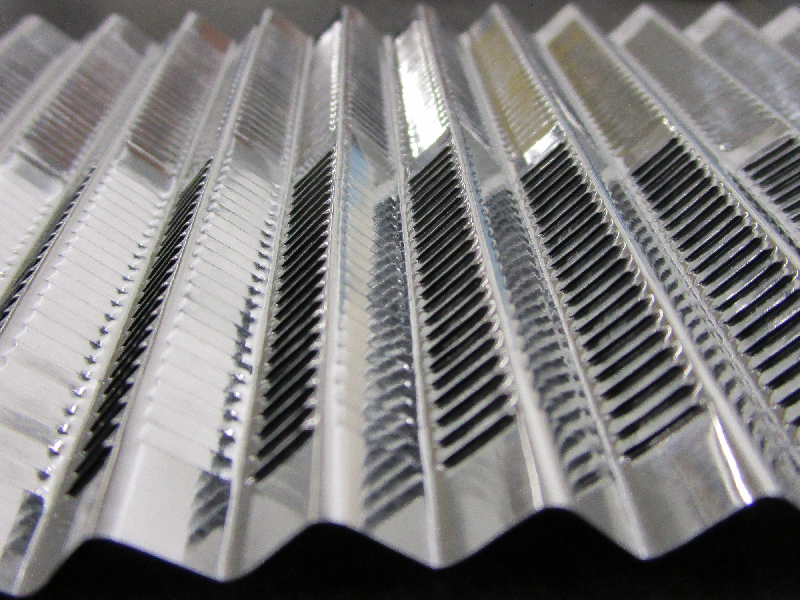

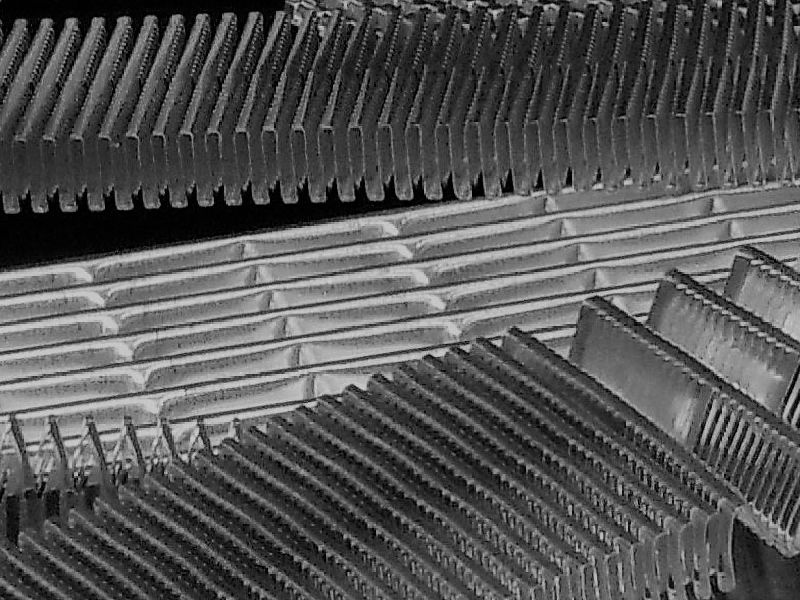

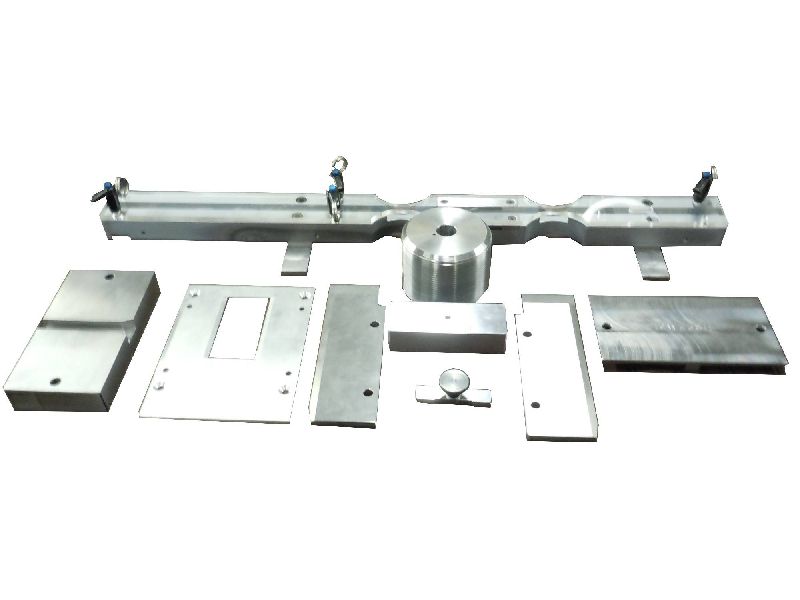

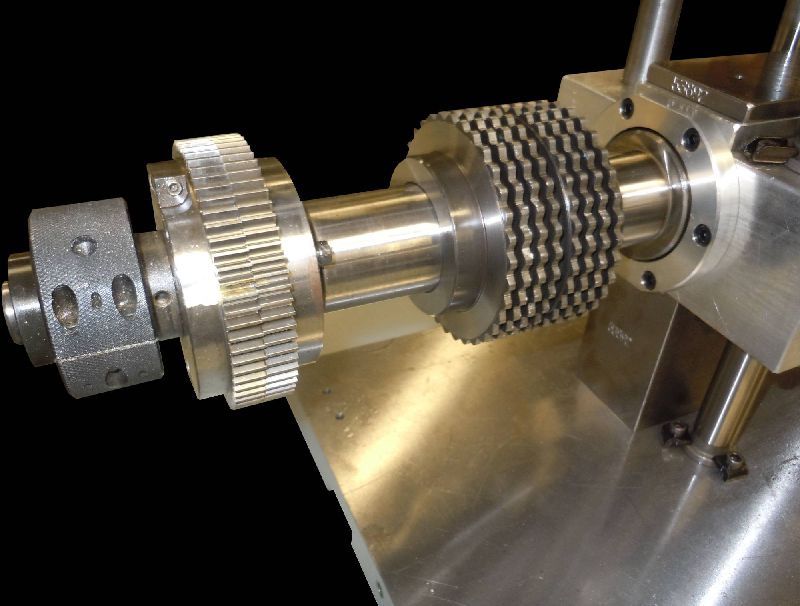

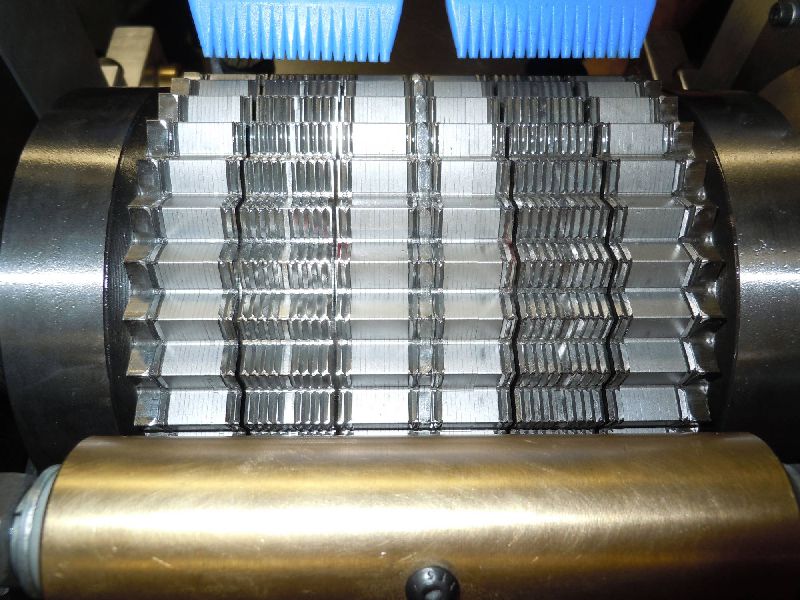

Custom Fin Roll Dies and Tooling

We will fully customize our roll dies and tooling to meet the specifications that you require based on the tolerances that are given out of the material that you seek. Carbide fin roll dies will provide a longer lifespan for your tooling whereas another material may be more cost effective to meet your current needs. Our precision tooling will ensure that the required fins per inch, amplitude, bulk transmission, louver angle, and fin length are satisfied in conformity with the adjacent tooling for your machine.

.png)